Sullivan Light Duty Wave Wall

- Constructed with Sullivan HD design

- Metal connection brackets create stability and add strength

- Diagonal steel reinforcement from wall leg to center beam

- Stainless steel exterior lag bolts – prevent rust

- Truss system hidden by 2”x10” outer members

Sullivan Wave Attenuators

- Attenuator boxes

- 5 timber beams or 7 timber beams tall

- Frames built from (2) 2”x10” laminated

structural timber beams - Floats incorporated into upper frame

Five Timber Beams Fully Assembled

- 3 sections connected by box-to-box connection plates

- 6 bolt truss tabs tie WA box to upper frame, reinforced with outside washer plates

Attenuator Box

- Diagonal wood bracing secures and

strengthens box timber members - Inside steel legs bolt through to outside

steel angle box legs

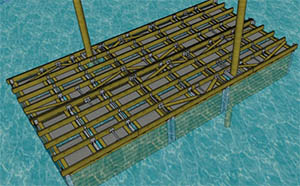

Galvanized Structural Steel Truss Frame

- Struts along top and bottom

- Diagonal struts tie box legs to truss and provides support for wall boards

- Truss design creates torsional rigidity

- Resists unforgiving wave action

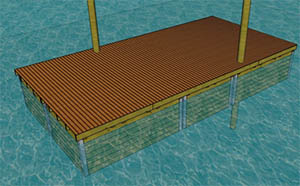

5 Timber Member WA w/ Upper Frame & Decking

- Splice block connection when wave attenuator is

constructed of multiple boxes. - Steel angle outside box legs extended to connect to upper frame

- Steel truss tabs between box legs connect to upper frame

- Step leg design aligns splice member

Sullivan Wave Attenuator Assembly

Integrated truss tabs stick upwards to attach the box truss to the dock frame

Sullivan HD frame, constructed with 2”x10” beams and preinstalled floats, is attached to the top of the attenuator box

Tab to tab center brace reinforces beams on each side of box

Internal pile guides are built into the frame,

with pile rollers and decking installed last

Completed attenuator boxes prepared for shipping

How Sullivan Wave Attenuators Work

Attenuator walls and box truss sit mostly below water level

Sullivan HD timber frame and floats attach to the top of the boxes

Surface fully decked as a useable dock